Behind the Scenes @ MSU: crafting MSU's iconic lanterns

V Kumar

April 2, 2024

On the first floor of the Infrastructure Planning and Facilities (IPF) building in the southern part of MSU’s bustling campus lies a hidden gem of craftsmanship: the Metal Shop. In this workshop, IPF metalworkers have been transforming sheets of copper into the iconic lanterns that grace the university's walkways.

The story of the refurbishment of these lanterns dates back to the late 1980’s, but for Metal Shop Supervisor Mike Ouderkirk, his contributions began with the 1999 Final Four NCAA basketball tournament, a pivotal event that led to significant campus transformations at MSU. In the wake of the celebrations and changes, the original campus lanterns were among the many fixtures removed. "After the campus renovations post-Final Four, they tore them all out and started bringing the lantern projects to our workshop," explains Mike Ouderkirk, IPF skilled trades supervisor.

Divided into three main areas–welding, sheet metal, and millwright–the Metal Shop team contributes its specialized skills to not only making lanterns, but also crafting HVAC ductwork, historic gutters, roof curbs, and any other custom metalwork on MSU’s East Lansing campus.

MSU’s commitment to excellence underscores IPF’s approach to facilities management as well. Years ago, as the original lanterns began to disappear due to vandalism, age, and deterioration, a concerted effort was made to preserve them, a result of the combined efforts of IPF and local vendors.

But perhaps the most ambitious objective of the IPF team is the quest for aesthetic coherence. Despite the diversity in current lanterns on campus, the vision is to eventually have all lanterns replicate this original design.

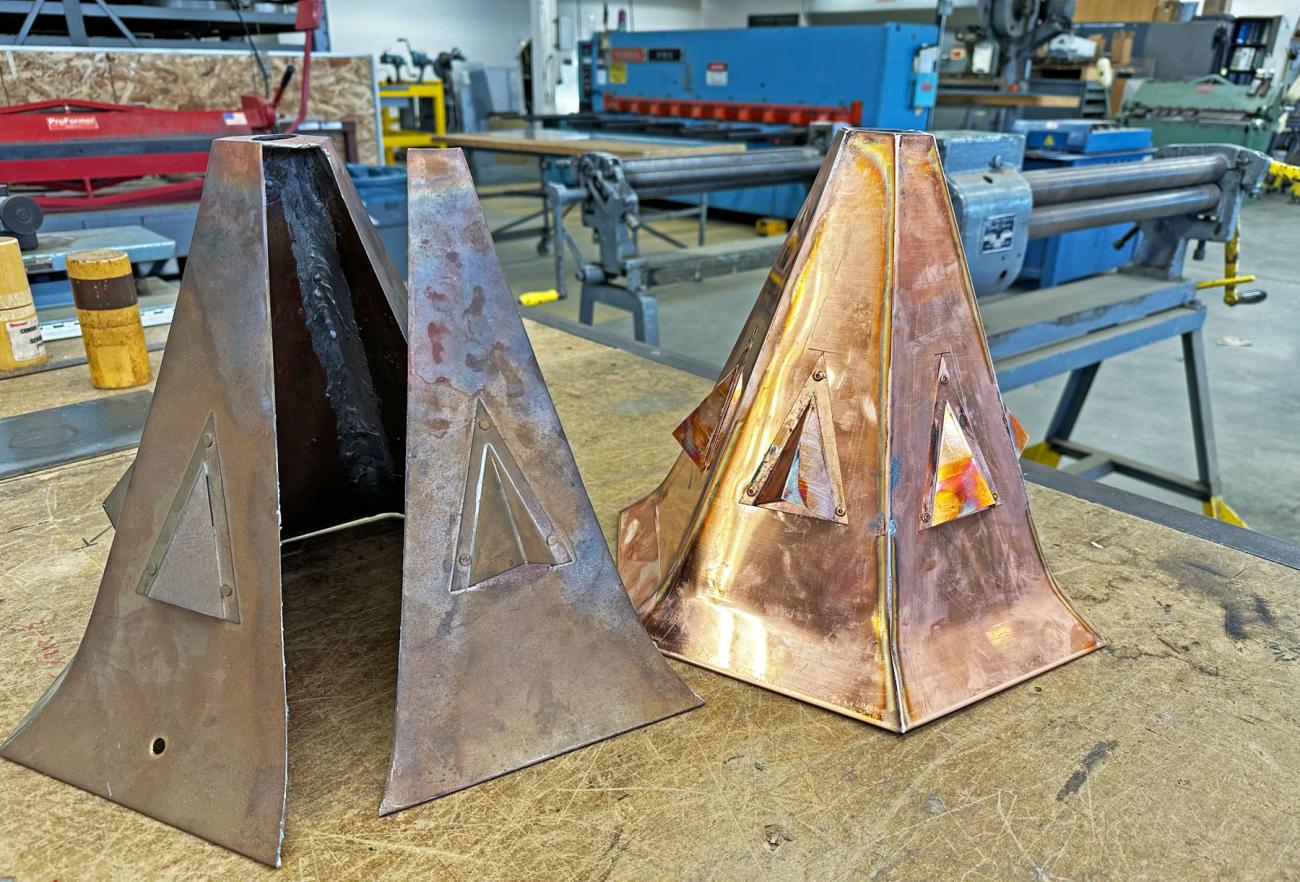

Each lantern begins as a solid sheet of copper. The Metal Shop team measures the original lanterns, then programs the measurements into a computer which lays out the pieces to minimize waste, and cuts them out using a CNC machine. Each lantern is then assembled and welded together by hand.

The trick is maintaining the classic look while embracing modern innovations to improve the functionality of the lanterns: for example, a small, hinged door for easy access to the light bulb, eliminating the need to remove the entire assembly to perform maintenance. The design team also incorporated thicker, more durable copper construction, unbreakable plastic lens panels, and improved electrical maintenance features.

The bulbs within these lanterns have been upgraded to LED, significantly reducing energy consumption without sacrificing performance. This improvement builds on the sustainability gains from the campuswide exterior lighting update in 2022. Eight of the new lanterns will be installed on the newly reconstructed Farm Lane Bridge.