New CNC machine reduces time and cost to manufacture precision components

Danielle Fowler

May 18, 2022

Sustainability is one of IPF's key missions, and its application can be seen in projects as big as the STEM Teaching and Learning Building and as small as a golf ball-sized piece of plastic.

In a Fee Hall classroom on the east side of the MSU campus, almost 30 adjustable chiropractic tables are arranged in long rows for the use of students of osteopathic medicine. Each of these tables uses four plastic components that enable users to raise and lower them. But the company that manufactures these parts no longer exists, and the brittle plastic is beginning to break.

The College of Osteopathic Medicine reached out to IPF for help when one of these components failed.

"Replacing the tables would be astronomically expensive," said Andy Van Halst, IPF machinist and millwright. "It makes much more sense for us to figure out how to fix them."

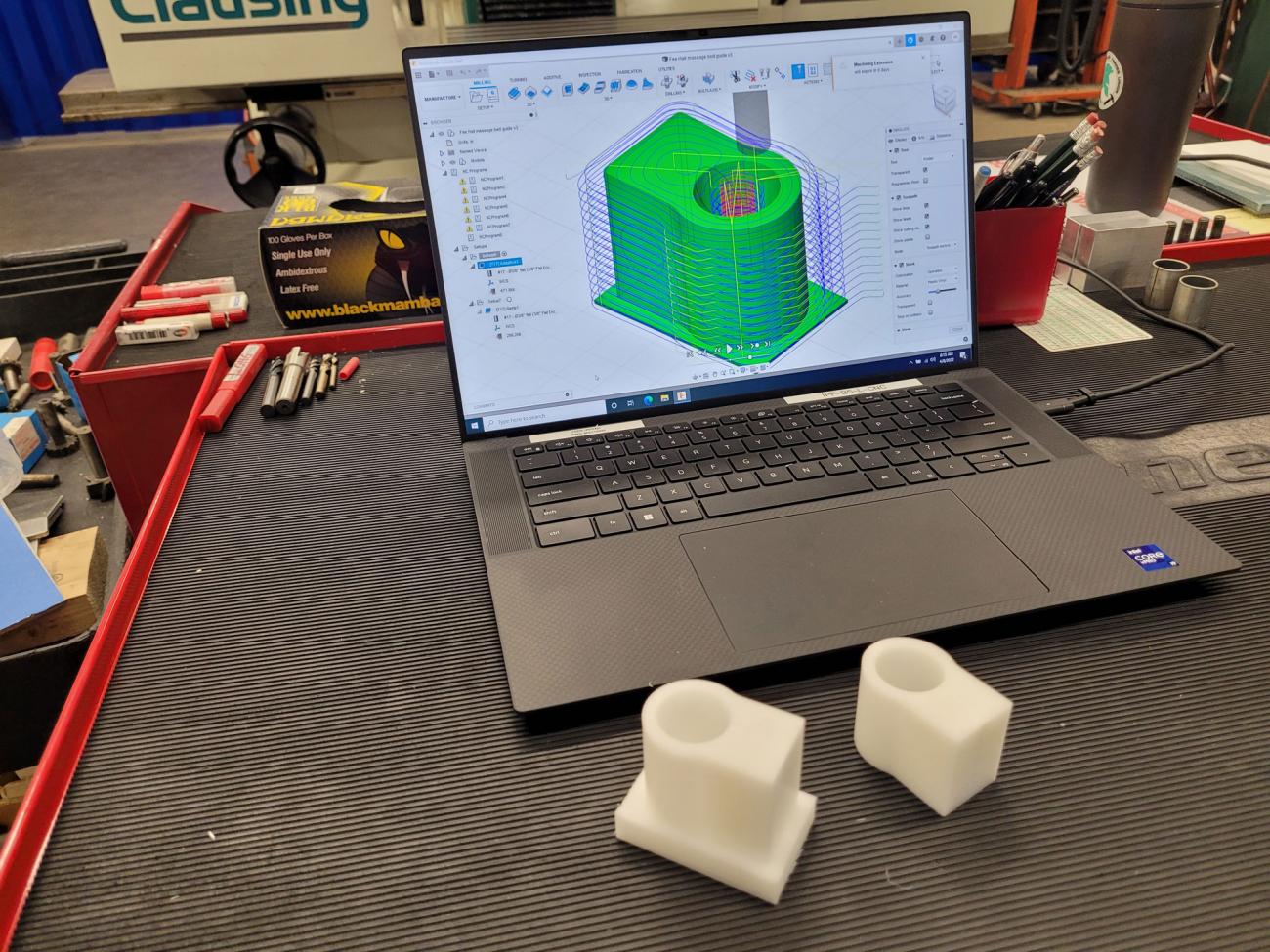

In the past, IPF machinists would create each of these components by hand. But with the addition of a Tormach CNC machine, the time and cost to manufacture parts like this has been drastically reduced. CNC, or computer numerical control machines, allow computer-controlled fabrication of items.

"It took about an hour for Andy to measure the piece and program it into the machine," said Craig Meyers, IPF machinist and millwright. They then run a simulation to ensure the part will be created successfully.

Once the part's design is stored in the computer, each unit takes less than twenty minutes to fabricate. "It takes longer to install the part than it does to make it from scratch," said Van Halst.

The part itself is made from incredibly strong polymer sourced from Mitsubishi and designed specifically for high-load mechanical applications. It's likely the rest of the mechanics in the tables will fail before the new plastic components do.

"The next work order we got from the College of Osteopathic Medicine said they had another one break," said Meyers. "So it's great that we can fabricate these fast, as we need them."